Jun. 20, 2025

Rock wool is the first choice

Fire incidents caused by insulation product occur from time to time, and their fireproof performance has become a hot topic of social concern. What are the differences in fireproof safety performance of common insulation materials in the market? We will reveal the truth for you through a simple flame combustible test

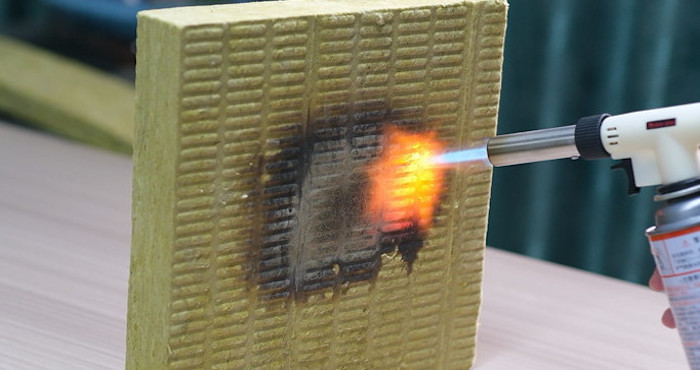

✅Grade A1 non-combustible: Huali rock wool board "fireproof strength"

When the flame continues to burn the surface of rock wool board, its burned surface remains intact, without any signs of ablation, and no smoke or irritating odor is produced. The inorganic mineral composition of Huali rock wool essentially determines its non-combustible properties, meanwhile the mature formula and stable process guarantee its excellent fireproof safety performance. The use of Huali rock wool in construction and industrial production can play a role in energy conservation, heat preservation and fire safety.

✅High temperature limitations of fiberglass insulation

Fiberglass, which is also a Class A non-combustible products, begins to melt when it contacts the flame temperature exceeding 400℃, while the fire temperature in a real fire can often reach above 900℃. Although fiberglass itself does not burn, it may cause structural damage to the fiberglass insulation layer in fires and other high-temperature environments, thereby affecting the overall fireproof performance. The fire safety of glass wool needs to be further evaluated in combination with the actual use environment.

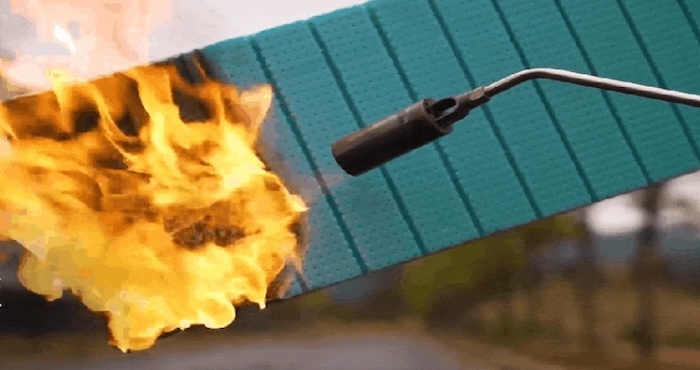

✅Hidden dangers of B1-grade: "burning traps" of polyurethane and extruded boards (XPS)

Unlike the first two inorganic materials, polyurethane boards and extruded polystyrene boards are organic insulation goods. Even if they reach B1 level (flame-retardant level) by adding flame retardants, there is still a significant fire risk.

Polyurethane board: It can be ignited after contact with flames, and a large amount of black smoke and toxic gases will be released during the combustion process. Although flame retardants can slow down the burning rate, the smoke produced by the decomposition of materials at high temperatures is extremely toxic and often becomes an invisible killer that threatens life in fires.

Extruded polystyrene board: It can also be ignited, and a large amount of molten dripping will be produced during combustion. These high-temperature drippings will not only accelerate the spread of fire, but may also ignite the combustibles below. It can be seen from the test that when the extruded board burns, thick smoke billows and the flame spreads rapidly, and the fire safety is worrying.

Through this flame test, fire resistance of different materials is clear at a glance. When selecting thermal insulation materials for buildings and industrial production facilities, the consideration of their fire safety performance cannot be ignored. Prevent trouble before it "burns".

Choose Huali rock wool with stable and reliable fire resistance to protect the safety of life and property.

Contact us and ask sample, we're glad to support !

Tel.: +86 131 0203 8097

E-mail: info@hualibw.com

Add.: No.126 Danjiang Road, Tanggu Development Area, Tianjin, China 300451